As a home or business owner considering the implementation of radiant floor heating, one critical aspect that you need to focus on is insulation. The performance of any heating system, including radiant floor heating, primarily depends on the structure’s insulation. Proper insulation serves as a cornerstone for these systems, and significantly contributes to their reliability, cost-effectiveness, and long-term operation.

The Importance of Insulation for Radiant Floor Heating

Radiant floor heating has emerged as an efficient and comfortable way to heat homes and businesses. To optimize the benefits of radiant heat, insulation plays a pivotal role. Here are some key reasons why insulation is crucial for radiant floor heating:

Efficiency

Insulation, specifically subfloor insulation, is a vital component that increases the overall efficiency of a radiant floor heating system. It helps to ensure that the heat generated by the system remains within the room and doesn’t sink into the concrete or leak away to the framing below, which minimizes energy loss and, subsequently, lowers heating bills.

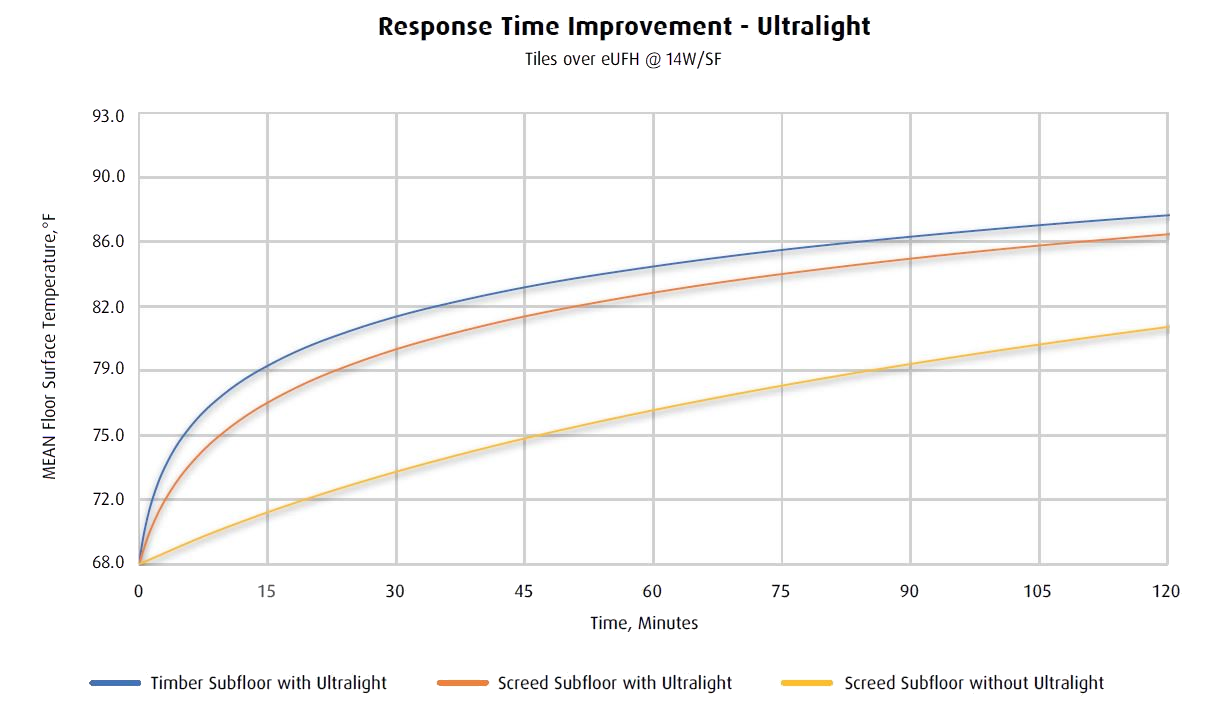

The inclusion of subfloor insulation boards like the 4-in-1 Ultralight™ board can reduce the heat-up time and the energy consumed during the initial heat-up phase. This type of energy efficiency not only decreases operational costs but also reduces environmental impact by placing less stress on the local electrical grid.

Heat-Spreading

One of the primary roles of insulation in radiant floor heating is to facilitate even heat-spreading. This eliminates the development of cold and hot spots and ensures a comfortable living environment.

Decoupling

Decoupling is another critical function of insulation. It protects the tile and grout from cracking due to subfloor movement. This ensures the durability and longevity of the floor finish, thus preserving the aesthetic and functional appeal of the flooring.

Acoustic Benefits

The inclusion of insulation also contributes to noise reduction, which adds to the overall comfort of the environment. By mitigating sound transmission through the floor, insulation enhances the acoustic performance of the space.

The Best Radiant Floor Heating Insulation Panels: Ultralight™ Insulation Boards

When considering insulation panels for radiant floor heating systems, Ultralight™ Insulation Boards stand out for their unique material composition and superior performance.

Material

The Ultralight™ Insulation Boards utilize a multi-layer design incorporating aluminum, non-woven fleece, and PEF insulation, which results in a versatile and highly efficient panel for insulation.

The board has three layers:

- The top and bottom layers are made of non-woven fleece that protect the tiles and grout from cracking due to subfloor movement.

- The middle layer is made of aluminum which reflects heat upwards for even distribution across the floor.

- The third layer is made of PEF insulation which reduces energy consumption and heat-up time.

Despite all these features, the board maintains a sleek profile with a thickness of only ¼”. This means it adds minimal additional height to the finished floor and dramatically reduces downward heat loss.

Performance

The performance of Ultralight™ Insulation Boards is remarkable. They effectively minimize heat loss, thereby increasing the efficiency of the radiant floor heating system. They can reduce the heat-up time by an astounding 76% and the energy used during the initial heat-up by 69%. This not only results in cost savings, but also contributes to environmental sustainability by reducing the load on the local electrical grid.

Moreover, the aluminum layer in the Ultralight™ boards ensures that heat is evenly spread across the floor, to enhance the user’s comfort. The fleece layers provide an added decoupling benefit that aids in preventing tile and grout cracking, thereby ensuring the longevity of the floor.

How to Install Ultralight™ Insulation Boards

Installing Ultralight™ Insulation Boards is a straightforward process. Here’s a step-by-step guide on how to do it:

- Preparation: Begin by cleaning and drying the surface where the insulation boards will be installed. This surface should be level to ensure the correct and secure placement of the boards.

- Priming: Apply a solvent-free primer to the cleaned surface. This primer will help to enhance the bonding of the adhesive that will be used in the next step.

- Application of Adhesive: Trowel out 1/4″ of a flexible, cement-based adhesive. The adhesive should be evenly spread over the area where the Ultralight™ Insulation Boards will be placed.

- Installation of Boards: Lay the insulation boards on the fresh adhesive grooves, making sure the red side is up and gray is down. The boards should be arranged with staggered joints to increase the stability and efficiency of the insulation layer. Ensure that the boards are pressed firmly into the adhesive to secure their position.

Note: It’s recommended to handle the Ultralight™ Insulation Boards with care during installation. Despite their lightweight nature, they should not be bent excessively or dropped. Also, ensure that no dust is present during the installation process to maintain the integrity of the boards.

Work with Warmup for the Best in Radiant Floor Heating Systems and Insulation Panels

If you’re looking for the best solution to improve the efficiency and performance of your radiant floor heating system, then look no further than Warmup. With Ultralight™ Insulation Boards, you can reduce the heat-up time by 76% and the energy consumed during the initial heat-up phase by 69%. This energy efficiency not only decreases operational costs, but also reduces environmental impact by placing less stress on the local electrical grid.

Contact us today and discover why Warmup is the go-to provider for superior insulation panels and radiant floor heating systems today!